Your Guide to Compliance and Accuracy

Are you curious about how a company determines which nutritional values appear on a food label? Or perhaps you have your own food brand and are unsure which method to use to meet regulatory labelling requirements in Canada or the United States?

The team at SNI can help. We provide clients with both regulatory and creative support for nutrition facts table (NFt) or panel (NFP) development, and we understand the nuances that apply to each method of nutrition analysis. Below, we explain the options and outline the options that come into play, particularly when preparing labels for Canadian and U.S. markets.

There are two main ways that a company can generate accurate nutrient values for their food product label – directly or indirectly.

1. Direct approach

This approach measures nutrient levels directly in the final food product after all ingredients have been combined and after processing. It involves sampling and submitting the product to an ISO 17025-accredited laboratory for analysis.

Laboratory testing is widely regarded as the most accurate method. It reflects the real nutritional composition of the finished product and accounts for changes caused by cooking, fermentation, drying, or freezing. It is also suitable for substantiating health or nutrient content claims and for supporting products that require enhanced nutritional disclosure, such as fortified foods or functional beverages.

Laboratory analysis can include the mandatory nutrients required for NFt/NFP, as well as additional voluntary nutrients such as B vitamins, minerals, caffeine, sugar alcohols, and omega-3 fatty acids. The results form the foundation of an authoritative and defensible label.

This approach is the most accurate.

2. Indirect approach

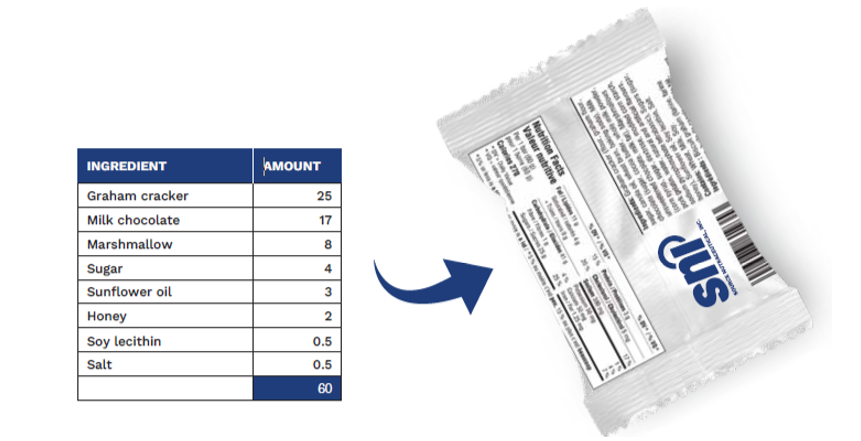

The indirect method calculates nutrient values using external data sources. This includes ingredient specification sheets from suppliers and reputable nutrient databases such as the Canadian Nutrient File (CNF) or USDA’s FoodData Central. These inputs are then compiled using software to estimate the nutritional composition of the final product.

Although this approach is less expensive and well suited to early-stage product development, it may be less accurate. Data from suppliers or public databases may be outdated, rounded, or insufficiently detailed to account for the effects of processing. If labels based on this data are used without verification, the risk of non-compliance increases, especially in the event of a CFIA or FDA audit.

This method is often acceptable for simple products, single-ingredient foods, or formulations with minimal processing. However, when producing nutrition labels for the final commercial version of a product, laboratory analysis is strongly advised unless the brand has complete confidence in its inputs and can accurately model processing effects.

This approach can be less accurate because it is difficult to assess whether the data is precise, it may be outdated, already rounded (limits precision), and it can be difficult to account for the effects of processing.

Using ingredient specification sheets to calculate a final nutrient content is usually more cost effective, and it is recommended in the early stages of product development. It is not always recommended for final nutrition labelling unless you trust the information available on your ingredients and can account for the effects of processing.

There’s also an option to mix both laboratory and software analysis to generate accurate results while also keeping costs to a minimum.

Many manufacturers choose to combine both approaches. This hybrid model provides a cost-effective balance by testing the most critical components of a formula in the lab while estimating the nutritional contribution of other ingredients using software.

For example, if a company offers multiple product flavours with a common base formula, the base may be tested in the lab while the flavouring components are modelled through database analysis. This method supports operational efficiency while maintaining regulatory defensibility.

Our regulatory team can assist with either option. Whether through laboratory testing or software-based calculation, we help ensure nutrient values are accurate, up to date and compliant. Our Creative Services team can provide the final Nutrition Facts table/panel as mechanical artwork that integrates seamlessly into your package design

What Nutrition Analysis Means for Canadian and U.S. Food Labelling

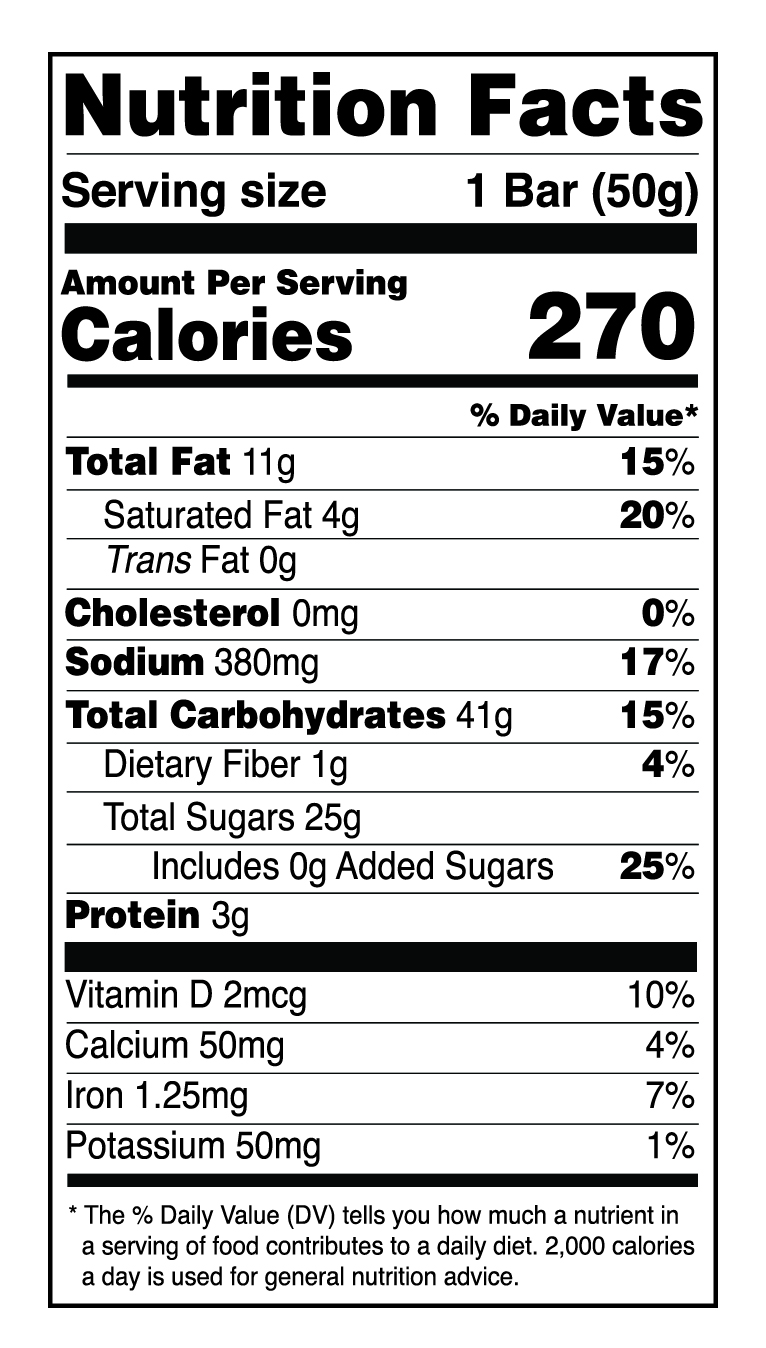

Nutrition analysis for Nutrition Facts table (NFt) or Nutrition Facts panel creation ensures that food brands provide precise, compliant and trustworthy label information. By converting recipes and finished products into exact measurements of energy, protein, fat, carbohydrate, sugars, fibre and sodium, brands satisfy Canadian and American regulatory frameworks and empower consumers to make informed dietary decisions. A robust analysis process underpins every new product launch or reformulation and demonstrates a company’s expertise in compliance.

Why Accuracy Builds Brand Credibility

Precise nutrition analysis strengthens consumer confidence by ensuring food labels reflect true composition. This transparency is especially vital for individuals managing dietary restrictions or allergies. It also reinforces brand credibility by preventing mislabelling and demonstrating a strong commitment to public health and regulatory integrity.

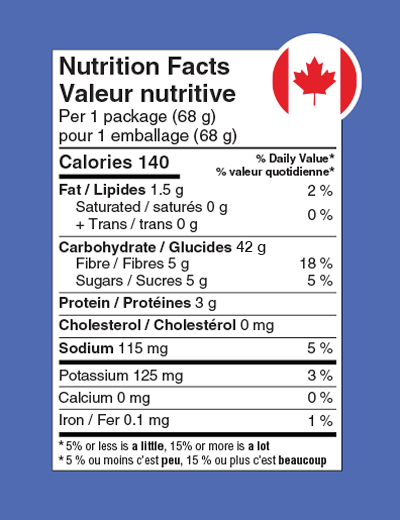

Canadian Regulatory Expectations for Nutrition Labelling

In Canada, nutrition labelling is governed by the Food and Drug Regulations and enforced by the Canadian Food Inspection Agency (CFIA). These regulations specify how nutrient data must be displayed in a Nutrition Facts table. Labels must follow rigid typographical and formatting rules, including font size, box layout and line thickness. Both English and French must be used unless an exemption applies. The format of the Nutrition Facts table is selected based on the available display surface, which must be calculated using CFIA methodology.

Serving sizes must reflect typical consumption patterns and be expressed in both household and metric units. Percent Daily Values must be based on the current Canadian daily reference values and displayed beside nutrient amounts. If a product makes nutrient content claims or health claims, the underlying nutrition analysis must meet the threshold values and be substantiated through laboratory testing or database validation.

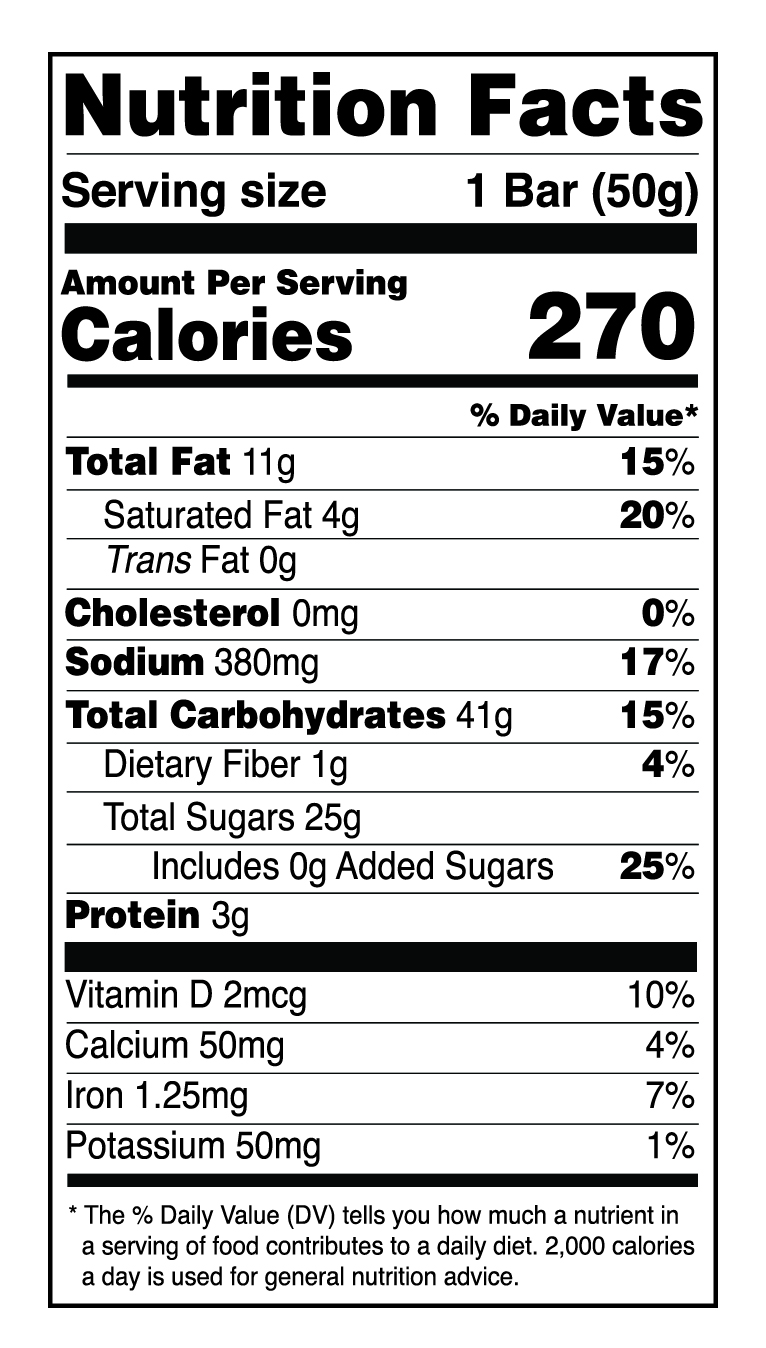

U.S. Nutrition Labelling Standards and Key Differences

In the United States, nutrition labelling follows a different regulatory framework, governed by the U.S. Food and Drug Administration. Labels use the Nutrition Facts panel format, which differs from the Canadian design in layout, serving size units and nutrient reference values. For instance, fibre and vitamin D are calculated using different methodologies. U.S. labels are not required to be bilingual and follow unique serving size conventions based on Reference Amounts Customarily Consumed.

Percent Daily Values are based on U.S. dietary guidelines and nutrition label formats are governed by Title 21 of the Code of Federal Regulations. Nutrient rounding rules and voluntary nutrient declarations also differ from Canada. These differences impact label design, nutrient threshold validation and consumer interpretation.

Ensuring Accuracy for Both Markets

Creating compliant and accurate nutrition labels for both Canada and the United States requires a clear understanding of the regulations in each jurisdiction. Businesses selling in both countries must prepare two versions of the label unless exempted by equivalency provisions. Nutrition analysis must be tailored to meet the applicable regulatory context and supported by defensible documentation.

Supporting Cross-Border Compliance

SNI provides end-to-end support for food businesses navigating these requirements. Whether launching a product in Canada, the United States or both, our team delivers tailored solutions rooted in technical accuracy and regulatory compliance. From nutrition analysis to label formatting and compliance documentation, we help brands meet domestic and cross-border labelling expectations with confidence.