“Risk comes from not knowing what you’re doing.”

-Warren Buffet

HACCP (pronounced has-sip) which stands for H: Hazard-A: Analysis-C: Critical-C: Control-P: Points is still the best system to manage food safety, to assess the risks and to implement preventive control measures.

HACCP was established in the late 1950’s by a group of scientists, the Pillsbury Company and NASA tasked to develop a way to ensure safe food in space expeditions. NASA had been using critical control points (CCPs) in their engineering branch, so they decided to apply it to food manufacturing. With several cases of foodborne illness outbreaks and contamination of glass in Pillsbury’s flour products in the 1970’s, the importance of proper hazard control was emphasized, and the methods developed by the team was soon adopted by the entire food industry and became part of the Codex Alimentarius best practices.

The purpose of HACCP is to control biological, physical, and chemical food safety hazards associated with the food product, ingredients and the food manufacturing process steps as a preventive approach rather than relying solely on final product inspection.

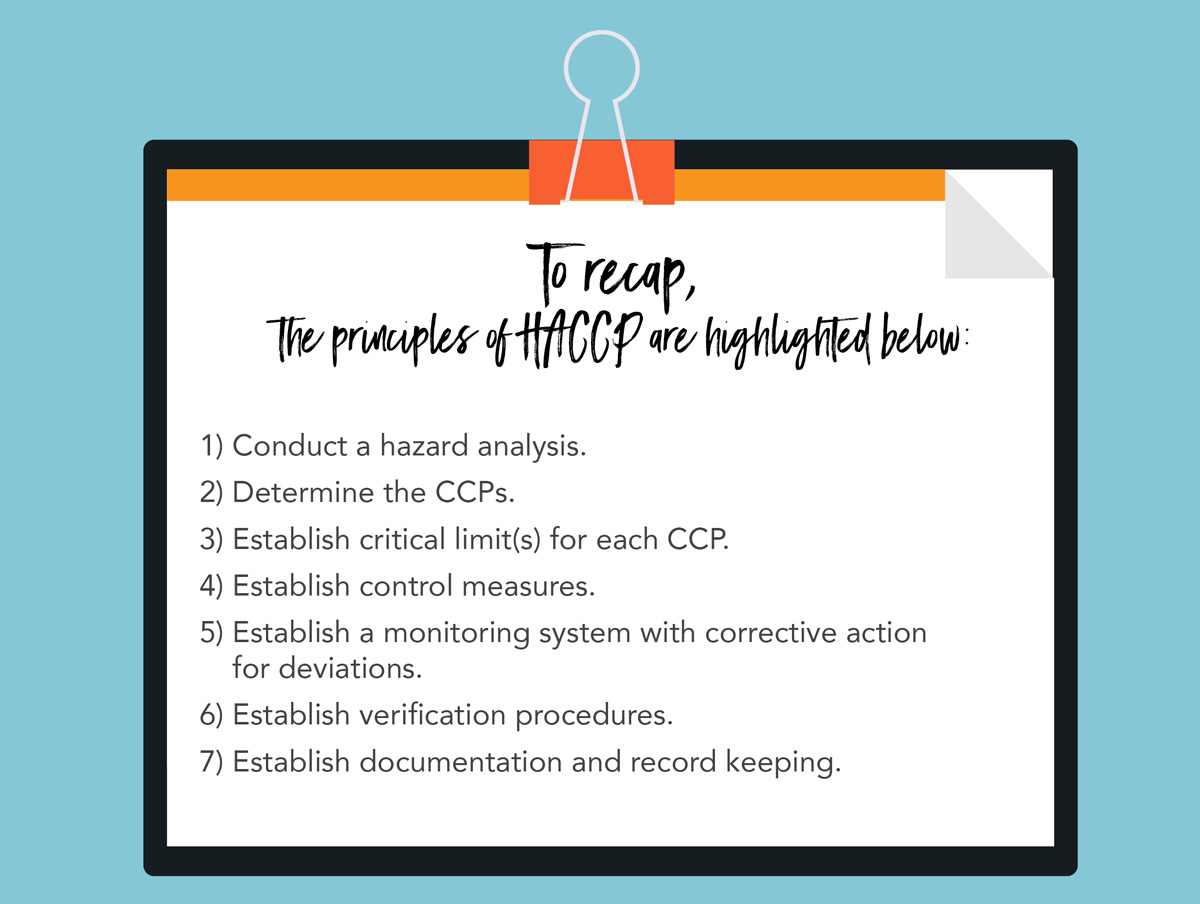

To do so, the manufacturer conducts a hazard analysis (risk assessment) of the potential hazards within the facility. These may be introduced during the processing of the food, enter the facility with the food ingredients, or even be introduced by personnel handling the food. All these hazards are to be accounted for and rated per likelihood and severity. Control measures are then established to prevent these hazards from contaminating the product. Control measures include but are not limited to Good Manufacturing Practices (eg. Pest control, sanitation, personnel hygiene).

CCPs-critical control points are those with a high severity. To control the CCPs, critical limits are established, so that if the CCP were to fall out of the limit a corrective action would be laid out for the personnel to follow. Monitoring procedures are also put in place to track the CCP as a preventive measure. Verification procedures, documentation and record keeping procedures are also established as part of the HACCP Program.

The result is a HACCP Plan which consists of eight to ten forms depending if the hazard identifications are combined in one form or separate.

Form 1 – Product Description

Form 2 – List of Ingredients and Incoming Materials (Ingredients, Processing Aids, Packaging Materials)

Form 3 – Process Flow Diagram

Form 4 – Facility Schematic

Form 5 – Hazard Identification (Biological, Chemical, Physical)

Form 6 – Critical Control Point Determination

Form 7 – Uncontrolled Hazards

Form 8 – HACCP Matrix

Scientists have developed a buttoned-up system that has assisted food manufacturing sites to take a preventive approach in their management of a safe food product for consumers.

As with any system, becoming successful requires a team effort in order to establish controls and carry out activities as assigned.